The sky’s the limit for Lukas Kobler, a forward-thinking entrepreneur who sees endless possibilities in what 3D printers can do. Kobler, a full-time engineering student at the University of Calgary, is juggling online courses while running his business, Yukon 3D Solutions, from his home in Whistle Bend.

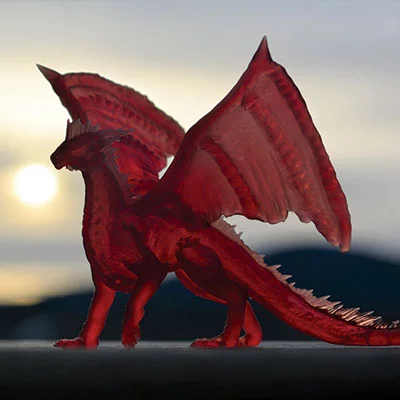

Some of the 3D prints he recently completed include Crewmates from the Among Us online game, small plastic modular drawers (designed by Kobler himself), a stag figurine, a red dragon, a rocket nozzle, a flexible phone case, Christmas ornaments, a replacement dashboard knob and a personalized keychain.

The eclectic assortment of objects speaks to the seemingly infinite number of applications when it comes to 3D printing.

“Some people are more on the technical side, they want prototypes or even end-use parts for engineering or do-it-yourself projects, whereas other people want trinkets. They want things that are cool to look at,” says Kobler. In the background, a Prusa printer is unassumingly transforming grey plastic filament into a TIE fighter from Star Wars. Kobler designed the print first and is now making two fighters for a client. Each will take the Prusa three hours to complete.

Kobler uses computer design software to make the actual model, which he then optimizes for printing through another program called “slicing” software. Then the design gets fed into the printer. He says it’s a steep learning curve. It took him six months before he was proficient in the software. There are easier options out there, but they’re not as powerful.

The young entrepreneur has several motivations for opening a 3D printing business in Whitehorse, most of which are related to sustainability. For example, he says that, especially during the pandemic, it’s important that manufacturing can be done right here in the territory. The printers are especially useful for mid-volume manufacturing of between 10 and 100 units.

Another reason for his interest in the technology is the potential for recycling plastics to make the filament used in the printers. He doesn’t have the equipment to do that himself yet, but it’s part of his plan for the future. The technology also has a do-it-yourself aspect to it that is particularly refreshing in these days of mass production and technological obsolescence. Kobler built his Prusa printer from the ground up, so he knows it inside out and can maintain it himself. In fact, he has used another model, an Athorbot from China, to print parts to upgrade his Prusa. Even during the manufacturing process, existing Prusas make parts for new ones. It almost feels akin to a rudimentary artificial intelligence. Kobler agrees. “Like self-replicating robots,” he says.

The technology used by the Prusa and the Athorbot is called fused deposition modelling or FDM. Kobler also has a printer that uses digital light processing (DLP) technology. It works with resin rather than filament plastic. The material is toxic, so Kobler keeps his set-up in the garage where he’s made a ventilation system made out of (yup, you guessed it) parts from his printers.

The FDM machine prints objects from the bottom up, so you can watch it in action. The DLP model prints from the top down and the technology is more complicated. The build plate dips into a vat of UV-sensitive resin and the print is built in layers until the part is hanging from the build plate at the top of the printer.

DLP is a more finicky process than FDM and more prone to error. However, the print quality is higher. Kobler has used the DLP printer to make parts for a rocket he’s building with other students at the University of Calgary. The rockets are 30 feet high and travel to an altitude of 30,000 feet.

Kobler’s hope is that people become more familiar with the technology and its boundless potential. The printers can be used to replace broken or lost parts on items that break, such as dashboards, as well as to create entirely new printed objects. As long as it can be imagined, and it can fit on the print board, it can be realized, Kubler says. “The possibilities are really endless.”

You can see examples of Kobler’s prints on the Yukon 3D Solutions website:http://www.yukon3dsolutions.com/